Tales From the Magic Skagit: The Story of Rozema Boat Works

The story of Washington is one in which waterways and watercraft have played a critical role. The Corps of Discovery followed the Columbia River to the Pacific Ocean, which decades earlier had brought European fur traders into contact with indigenous people whose survival depended on the fish and whales they harvested from those waters.

As the Europeanization of the Pacific Northwest continued, so too did maritime trade. Further inland, the rich soil and dense forests of the Skagit Valley gave rise to agriculture and logging, which depended on river transportation to move goods and connect communities.

It’s therefore no exaggeration to say that it is no more possible to imagine pioneer life in Washington without boats than it is to imagine it without horse drawn conveyances. And while steam locomotives and the internal combustion engine would redefine the meaning of “horsepower,” boats have remained a constant in the life and economy of the Skagit Valley. We are water people. It comes as no surprise then that the building of boats has been part of our state’s industrial base since Lewis & Clark copied the techniques of the native peoples they encountered in fashioning the dugout canoes that enabled the earliest exploration of Washington.

If you’ve ever driven along Bayview-Edison Road, you’ve no doubt noticed the former Odd Fellows Hall that houses a long time boat building operation in the Skagit Valley. This is the story of Rozema Boat Works, a family business that has been part of Washington’s maritime legacy since its founder immigrated here from Holland in the mid-20th Century. Here’s how it came into being, as told to me by one of its third-generation owners, Dirk Rozema.

Dirk Rozema

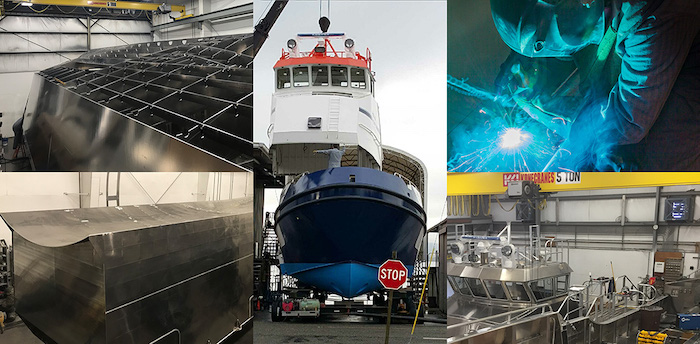

The simple answer to the question “What does Rozema Boat Works do?” is that we design and build boats for a wide variety of people, companies, and industries. If you wanted a particular type of boat, we would propose a design and a cost and build the entire thing from concept. In other words, we are totally custom. Every now and then we may have a production run of a custom boat, but we don’t fit the mold of the small yacht production business — we don’t design for a market or price point. We have done variations of successful designs, but we do have a size range that works best for us, from about 30-foot and up. We’re also good at complicated vessels — we have that know-how. We have models we are constantly modifying to a particular hull size.

Our biggest challenge is being stereotyped as only doing certain types of boats, like oil spill response boats. We’re well known in that market, and people in that niche industry call us. But that is still just a boat — although a complicated one. If someone wants a passenger boat or a landing craft or something different, they might not think of us. I try to make sure that people know that whatever it is, for us it’s still just a boat that we build to your ideas and needs.

My grandfather and father started the business in 1955. The stories I’ve been told go back to Holland — the old motherland where my grandfather and father were born in a little town called Bedum in east Holland. It’s near a larger town called Kroenig, which is the biggest city in northeast Holland, with a lot of canals and a rich boat building history.

My grandfather, Alle (pronounced “Ollie”) Rozema, went into an apprenticeship in boat building and learned what was called “lofting.” It is a process that is done to this very day, but with computers. Essentially, you take a drawing or design of a boat and transfer it into something a shipyard can use. Even in the ‘80s, when I was a kid, it involved drawing the boat out on a floor so you could generate full-size patterns that could be taken to the shop and laid onto metal and then cut out to build the boat. It was great for what we refer to as “faring” out the lines of the boat. You can draw a picture of an 80-foot boat on paper and be off just a pencil line, but that could translate into 1/4 or 1/2 an inch of “unfarness” in the boat, like a bump. The lofting process allows you to stand back and look at it and make sure that all your lines are straightened out and then make your patterns off of that.

All boats were built like that. My grandfather’s lofting skills were really famous. Doing that by hand is a lost art today. That was his trade, and he was ultimately a foreman and “loftsman” for a medium-size shipyard in Holland. Then the war (WWII) happened, Holland was invaded, the town was occupied by the German forces, and my grandfather was forced to build boats for the Germans.

After the war my grandfather was just one of those guys who wanted to work for himself, and he didn’t feel that he could get that opportunity in Holland — so in 1949, at the age of 40, he left behind a nice home and came out here with an unknown game plan. He had a relative or two who sponsored his family, so he picked up odd jobs and worked his way into a boat company, then created a partnership with a couple of guys in Anacortes and slowly built the business. Being a stubborn guy, he wanted to buy his partners out, but they wouldn’t let him do it quickly enough. They probably would have over 6 to 12 months if he had been patient, but that wasn’t Alle Rozema — so he bought this place with every dime he had. He was left with $100 in the bank, bought this dilapidated building on a mud flat, and started building wooden skiffs. He slowly built a reputation boat by boat, starting from zero.

The original building that Rozema Boat Works is in was an Odd Fellows Hall, and somebody else was already building boats here and lived in the room we’re now sitting in. The boats were built downstairs. There was a set of rails that went down into the mud flats, and they would bring boats in at high tide and winch them into the shop.

My memories of my grandfather (Opa) are vague. I was only nine when he passed away from a stroke, so my memories are more of him sitting in his chair and trying to rehab. I don’t have a memory of him in his prime. The house he lived in is on McClean Road, near the intersection with Best. My dad was apparently better at taking direction from my grandfather than his older brother Fred; based on the stories I’ve heard, Uncle Fred and my grandfather’s temperaments were somewhat similar, so they just couldn’t work together. My dad toed the line and started working here when he was pretty young, about 10 or 12 years old, sweeping the shop or holding a drill. By the time he was in high school he would be here before school, then go to school and come back here afterwards. It was like a small family dairy in terms of time commitment, but it was just my dad and not his siblings.

Although my dad learned a lot from his father, Opa didn’t really pass on a lot of the knowledge he had. He really used my dad more as cheap labor and didn’t take the time to teach him about what he was doing and why…like lofting. My dad learned how to loft from a Norwegian designer that he hired out of Bellingham when he built his first Bristol Bay boat, after my grandfather died and my dad took over the business. It was that guy, Ralph Horn, who showed my dad and me how to do it. We drew boats right where our offices are. That was our loft floor where we drew out the boats full size. Opa never taught my dad anything about it, and it has caused my dad some grief in thinking back on it.

It was a shock for my dad to have to take over this business. He wasn’t a business man by nature — he was a worker, and he’d never been taught anything about the business, and here he was left to pick it up. Now that I’ve gone through the age that he was, I can easily imagine how tough it was to not only lose your father but to have everything dropped on your lap with no real training. He was just working — welding and hammering every day — and then one day he’s having to run the whole thing, which is why I think his hair turned white not long after. My mom, whose family was from Ireland and had originally emigrated to Canada, stepped in to help on the business side, but neither one of them knew much about business.

My brother Jason and I are now the business owners. Jason is more on the operations side, and I’ve taken on the role of design — and with that comes sales and marketing and writing the specs for proposals. We both share project management responsibilities. We can’t do it all, and we talk daily about where we’re at and where we’re going to be in the future.

Constructing a boat is a complicated process. The sales part of the process is very elusive, but at some point someone decides to buy a boat. The next step is the customers telling us what they want and for me to design the boat based on that input, then doing the layout and determining that we can efficiently complete it. It is very satisfying to me to come up with something that looks good and functions well, but that is also highly constructable. Then I have a team of outside engineers that we work with review the design to guarantee stability and other structural engineering considerations.

At this point we go into the lofting phase. We’ve worked with the same person in Kirkland for 20 years at this phase of layout and getting the pieces created. He makes the pattern from a CAD drawing that we draft, then that pattern goes to an aluminum supplier who cuts it out, and we assemble the pieces here and do all the other work to complete the boat. If we had more space we would have our own cutting equipment. The pieces of the boat are placed on a machine that cuts them out and numbers them according to our assembly plan. At this point its a lot of welding and fitting…and it’s not like it’s brainless work. There is still a lot of skill to get these pieces right. If you’re off by even an eighth of an inch per part the accumulation of error will be a huge problem. The criticalness of putting everything together just right can’t be overstated.

You really have to have great skill in installing as well. The aluminum work is at most a third of the boat, then you have installation of equipment, electrical, carpentry…a lot of project coordination…brackets, routing of wiring, exhaust systems — it all comes together at the bridge and the wheelhouse. We make the interior look really good as well. And then it has to be delivered. We launch in Padilla Bay and then do sea trials. When we are delivering a boat to a buyer it has to be in turn-key condition. They have to be proven, and we have to correct whatever needs correction and issue a warranty for reliability and follow on service if necessary.

We typically have about a dozen people working here at any given time, but we can push it up to 20 if need be. The shop is really humming at 20. You have to make sure that the people with the skills all this requires have enough to do so they don’t leave on you.

When I took over the business it was struggling…the environment for boat building was difficult. But it is an interesting business, and there are a number of boats that I’m really proud of. We think of them as flagship boats. Of the three Rozema brothers, I was the one who had always planned on doing this business. Jason kind of fell into it by virtue of having a literature degree, but I knew in high school that I wanted to do this and I went to business school with this in mind all the way. I don’t know that it was my parents’ plan, but it was my plan. Even our youngest brother, Nate (who became a teacher), still relates to the business and loves boats, so it is part of all of us. Rozemas are boat builders.